The Real Art of Fake Food: Behind the Hyper-Realistic Replica Dishes You See in Restaurants

PUBLISHED November 2nd, 2021 05:00 am | UPDATED November 10th, 2021 10:52 am

You see them in the display window of any Japanese chain: crisp tempura that time never turns soggy, bowls of ramen forever glistening as though hot off the stove, unmeltable parfaits that still look creamy enough to lick. As many children do, I used to press my nose right up to the glass, trying to suss out what was behind all that mouthwatering detail. In fact, for an embarrassingly long time, I firmly believed they were real food – just preserved with chemicals like some kind of mummified meal.

In food-obsessed Singapore, Vanessa Yeo has encountered that same fascination everywhere she goes. “Talking about fake food has saved me from countless awkward dinner conversations,” she jokes. “Maybe it’s a Singaporean identity thing, but food has that special ability to connect people. I could talk about the texture of curry and how to accurately reproduce it until there’s no one left in the room to listen.”

Vanessa isn’t a chef – she’s a fake food artist, a rare breed in Singapore. Through her studio Itchyhandsvan, she cooks up hyper-realistic replicas of local favourites for restaurants and brands. Her ingredients are a mix of resin, clay, PVC, silicone rubber, and paint – but in her hands, they transform into the likes of laksa, chili crab, and curry puffs that look good enough to eat. It’s a local spin on the art of fake food first perfected by the Japanese – what they dub sampuru.

Sampuru: A Century-Old Art

Legend has it that sampuru – a word derived from the English ‘sample’ – was born in the small town of Gujō Hachiman, when businessman Takizo Iwasaki saw a drop of hot candle wax falling into a puddle. When he swirled the puddle of cold water, the wax blossomed into the shape of a flower – and this vision kindled his belief in wax’s potential to create replicas. In 1932, he founded the replica foods firm till today known as Iwasaki Co, and crafted his first wax model: the popular omu-rice.

Iwasaki’s timing was impeccable. At that time, more restaurants were opening with a range of newfangled creations, including Western-inspired dishes dubbed yōshoku. Sampuru served as a tasty visual hook to draw customers in. Post-WWII, sampuru came in even more handy during the occupation of Japan by American troops – foreigners who couldn’t read Japanese menus could simply point to what they wanted.

Sampuru swiftly made a splash in Japan’s restaurants and department stores, with lasting effects – today, the art of fake food is a multi-billion-yen industry. This industry remains centered in Iwasaki’s charming hometown of Gujō Hachiman in Yifu Prefecture, where artisans hone their skills for decades to handcraft around 80% of Japan’s sampuru. For tourists, there’re also cutesy souvenirs to snag by the dozen – okonomiyaki magnets, bowls of udon dangling from keychains, phone cases mimicking sashimi platters.

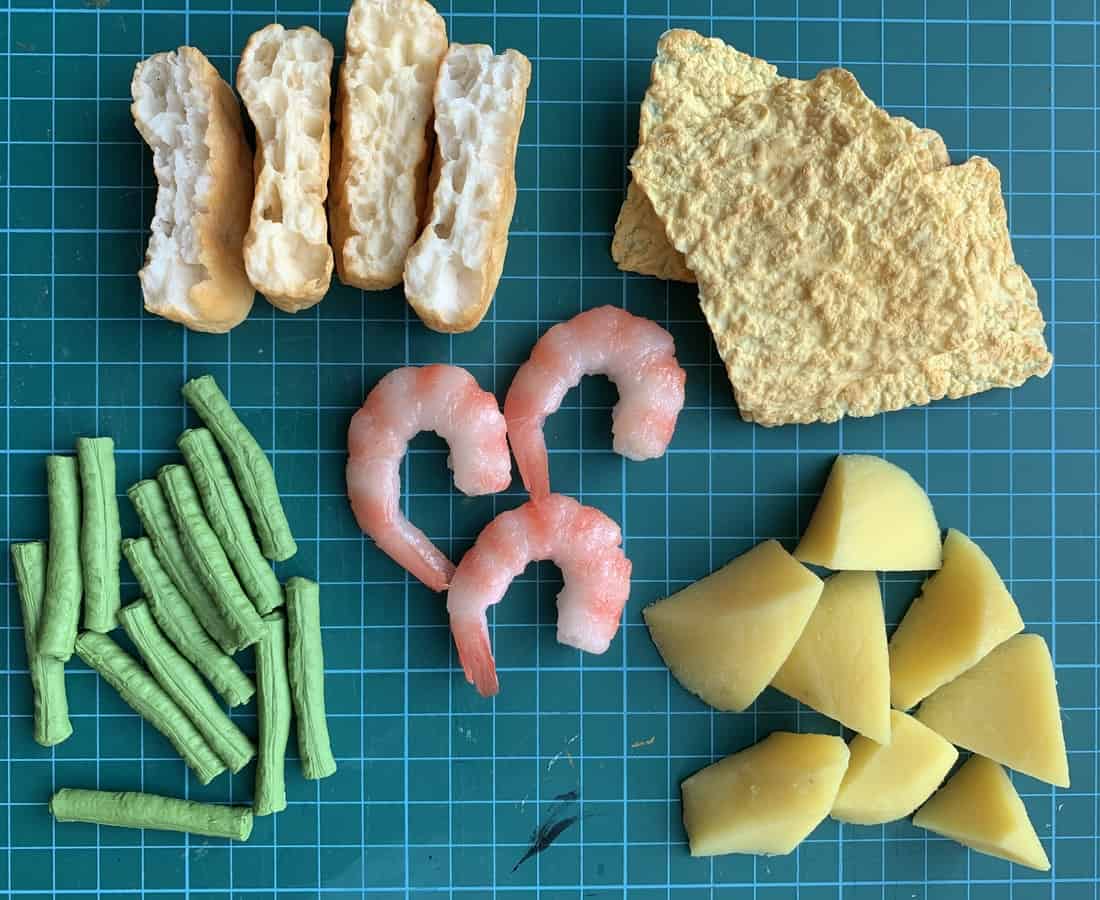

These days, food replicas are typically crafted from plastic, silicone, or resin – a step up from wax’s tendency to melt in summer heat. Restaurants freeze and send the real food they want replicated to sampuru craftsmen, who dip the dish in silicone to make a mold. Liquid plastic is then poured into the mold to capture the food’s texture, followed by painting and airbrushing to mimic its colours.

Even more laboriously, many ingredients are too delicate to simply be dipped into a mold. Instead, each intricate detail calls for shaping by hand. Liquid plastic must be dripped in strings at a precise height to form tempura batter; melted plastic is piped onto cakes the way you would real icing; plastic vegetables are ‘chopped’ with real kitchen knives. It’s no wonder it can take years of training to be a fake food artisan – perhaps as long as a chef.

Faking It Till You Make It

Outside of Japan, fake food has carved out a place at the table too. In Singapore, you might spot replicas in the windows of seafood restaurants or in museum exhibits of local dishes – each shaping a rich story of Singapore’s cuisine. Many of these are still created abroad – Philip Lim from Plastic Food Models, one of the first suppliers of hawker food replicas, shares that he works with mold makers from Japan and Taiwan as “liquid PVC is a restricted raw material in Singapore”.

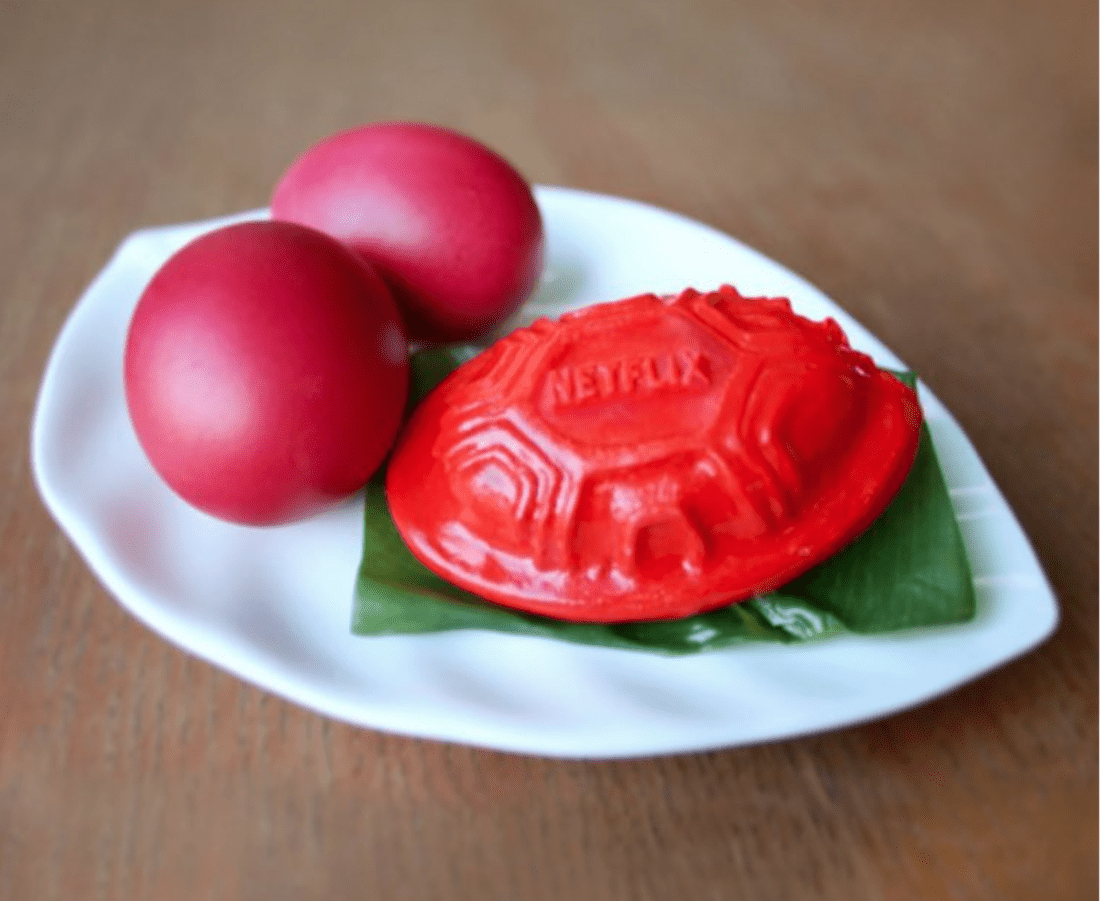

Regardless, a handful of local makers like Vanessa have sprouted up. As a creative in the advertising industry, Vanessa’s first foray into food replicas five years ago came as part of social media content for her client, Netflix. “Netflix had just launched in Asia, and I created custom Netflix-branded ang ku kueh to celebrate their first full month of being in Asia,” she explains.

Unlike sampuru artisans, this self-taught maker’s only teachers were YouTube and good ol’ trial-and-error. “I watched a few YouTube tutorials about making miniature food before I started. That was the closest I could find to making 1:1 fake food models,” she explains. “It was mainly learning from making a lot of mistakes.” Still, she got the hang of faking it quickly. Fake mooncakes were her next project, followed by a series of food trophies to promote Netflix’s first original documentary series, Chef’s Table.

Making The Mundane Mouthwatering

Since then, Vanessa has served up a slew of heritage dishes for local brands, including Old Chang Kee curry puffs and salt-baked chicken for PokPok Keh. A milestone in her culinary journey, she tells me, was the humble soft-boiled egg – a marvel of glistening surfaces and translucent textures. Cooking an egg that looks runny enough to burst with the tap of a spoon, yet is solidly made of polymer clay, resin, and a sprinkle of ‘black pepper’ sand? It’s a feat that takes her four weeks.

Singapore’s national dish of chili crab is hard to master as a chef, and even tougher to replicate from resin and clay. “I made two crabs for No Signboard Seafood in Geylang: one chili crab and their signature white pepper crab,” she shares. “What was challenging was the many components to the dish – one crab took about two months to finish, with a lot of time spent sculpting and getting the colours right. When clay cures, its colour changes, so I had to take that into account.” Fortunately, she loves eating crab, so “replicating the textures of the meat and sauce wasn’t too unfamiliar to me.”

Foodie or not, the unbelievable realism of Vanessa’s ‘dishes’ is enough to inspire fresh appreciation for our everyday eats. The sheer intricacy of colours needed to breathe life into a simple egg, the way the rich gleam of her chili crab gravy is perfectly calculated to induce drool – once you start noticing each detail, it’s easy to see the everyday beauty in our local dishes with new eyes.

The next challenge already on Vanessa’s plate is another beloved Singapore treat: bak kwa. “It’s challenging because if you examine bak kwa closely, the meat is made up of different hues of red, as well as translucent white bits of fat. On top of that, the burnt ends have to be done right, with just enough char for that tasty barbecued look. It’s taking the same care and effort to craft this as it takes to cook the actual meat – I have to make mundane clay look incredibly tasty.” Just from her description, I’m hungry already.